No. It is not a kit.

Some boats are built from kits, but this is not one of them. The best analogy is to say that building this boat is a lot like building a house. An architect gives a builder a set of drawings and you go from there. In this case, we also got some DXF files that could be used to CNC cut the shapes of the frames, primary stringers and a strongback on a CNC router, but that represents a labor savings of about 2% in the grand scheme of things. What it does do is give you a more precise “foundation” from which to begin.

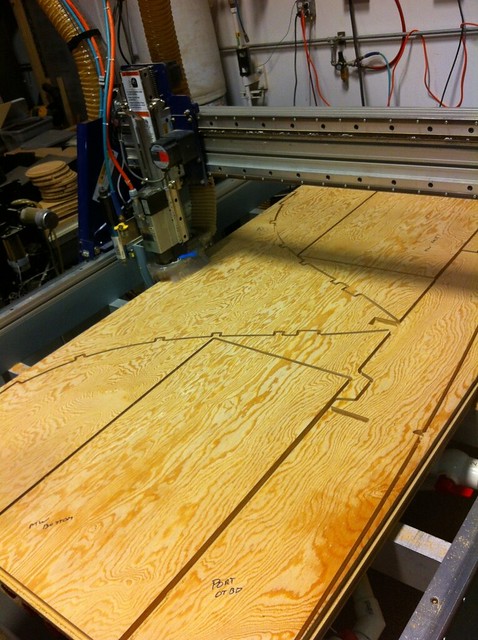

Here’s a quick shot of the CNC cutting some parts. I love watching these things go. And thanks a ton to my friend Chris at VectorPickle who helped with the cutting!

Regardless, the majority of the material is sourced as either marine grade plywood in 4’x8′ sheets, or rough sawn 4/4 or 8/4 V.G. Doug Fir, Western Red Cedar, Teak, or other form of rot-resistant lumber from a lumber yard. These are then cut or milled to shape on a jointer/planer/tablesaw, and then fit by hand to the boat. In fact, nearly every one of the pieces that’s cut by the CNC router requires hand fitting by the time it’s all done. We are truly building a boat.

-Ben