Enough with the distractions. We’re back to work as of Monday morning. I didn’t write yesterday because I’ve lost the cable to get the pictures off my camera and I figured nobody reads anything that doesn’t have some eye candy. Today I went and got the spare cable from the big boat.

Yesterday and today were both frustrating, but for different reasons. Yesterday we began by pulling the remaining metal staples from the port side of the hull. Our hope was that the UPS guy would show relatively early in the day – usually it’s by around 10 or 11am. Unfortunately, by 2PM there was still no sign of him, so we pulled the plug. My dad went home and I puttered about waiting for Mr. UPS, doing some assembly work on the CNC router kit I recently purchased.

Blisters notwithstanding, here’s a big part of the reason we’re waiting for the plastic stapler. Normal staple holes from a normal staple gun look like this:

But pulling the handle that shoots those buggers a couple thousand times a day is a recipe for angry hands. So we bought a narrow crown pneumatic stapler (which is what Home Despot had in stock). Here’s what those holes look like when the staples are removed.:

No bueno. And if you zoom out a bit, you can see the extent of the destruction. Note that in a lot of places the grain of the plank actually splits a bit on either side of the staple. This isn’t a fatal issue, but it does create a lot more work between this layer and the next:

Anyway, while my dad was away I did a light sanding on the hull to get the biggest of the ridges and bumps out as well, but … and this becomes relevant when we get to the source of today’s frustration – it didn’t occur to me to do a more meaningful fairing of the first layer to fill in the staple holes and minor gaps between boards. I just figured we’d put a thick layer of adhesive between layer one and two, and that we’d start planking first thing this morning.

As mentioned, at 4:00 or so, the stapler arrived.

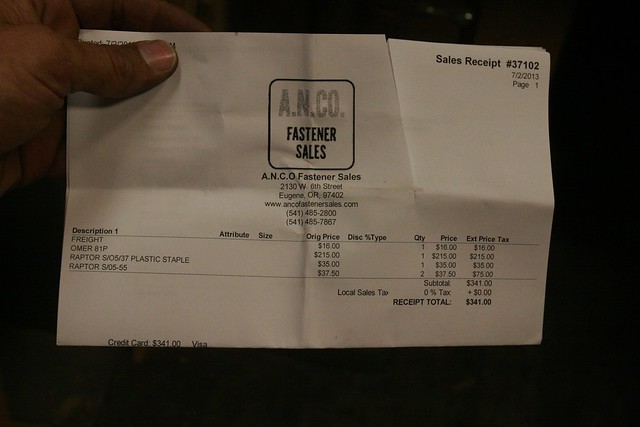

All hail the stapler that shoots plastic staples, and the staples it shoots:

All hail the unfortunate price tag!

So the first thing we did this morning was to take that handy new stapler and finish the portions of the port side that weren’t yet done. We had to dial the pressure in to get the right penetration, but that only took a few staples to get right. Once done we were off to the races. Here you see, in glory that can really only be appreciated if your hands are thoroughly blistered from pulling metal staples, planking laid with staples that never need be removed.

You also see a bit of fairing compound smoothed over them. Which is the source of today’s frustration. As I looked more closely at the hull today, I realized that it was going to be a giant pain to get a gap-free bond between the second layer and the first without doing some more aggressive fairing first.

This warrants a brief side note.

When building a laminated structure such as a cold molded hull, it’s really, really important that there be no air trapped in your laminate. Air is not strong. Air creates opportunities for condensation, which can lead to rot. Air is bad workmanship. When laying a new layer atop an existing layer, you want the adhesive to completely fill the gap between them. The layer of adhesive can be thick, but you really want no air in there.

Okay, so with all those little staple holes, minor gaps between planks, and ridges where one plank meets another, it just started looking really unlikely that we’d get a good layup without a ridiculously thick layer of epoxy, which would be heavier, costlier, and somewhat less strong than a thinner one. And so, we decided to shoot today in the head and smear a layer of fairing putty on the hull. Once that’s done, it needs to cure overnight.

So tomorrow is really what Monday should have been. The day we move on to layer two.

First thing in the AM we sand the putty smeared hull down to a more workably fair surface, and then we can get to planking. I’m hoping if we push really hard we can do both sides in a single day. It will be a loooong day, but I’d really like to get all three layers of side planking done by the end of Thursday. My dad’s away over the weekend, and while I can’t really move to planking the bottom withouth a helper, I can do a fair bit of prep work once the sides are done.

I did find a silver lining in today’s shortened day though as well. More work on the CNC. It’s getting close!

-Ben